|

||||||||||

|

|

||||||||||

|

||||||||||

|

|

||||||||||

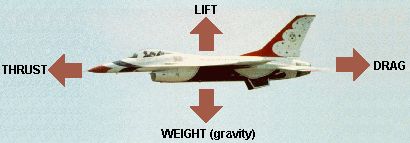

A rocket primarily travels in a vertical direction rather than the horizontal flight path followed by most aircraft. The same four forces of flight still act on a rocket, but the directions in which they act and their magnitudes vary as shown below.

In particular, the lift force acting on a rocket in vertical flight is usually pretty small. The other three forces, however, all directly impact the maximum height the rocket can achieve. Weight is a function of how each component of the rocket is designed. The lighter the rocket is, the higher it will be able to go all else being equal. Thrust is generated by the rocket's motor. The more thrust the motor produces, the higher it will go. However, neither of these forces is heavily dependent on the nose shape. The force that does vary significantly with the shape of the nose is drag.

Drag is the force that resists the motion of the vehicle through the air and opposes thrust. The lower the drag, the higher the rocket will be able to go. Drag is due primarily to friction between the surface of the vehicle and the fluid through which it travels, that fluid being air in the case of a flying object. Drag results because the molecules of a fluid must be moved aside as an object moves through it. This process takes energy, and the energy needed to move the fluid aside reduces the remaining energy available to move the object forward. Drag is minimized when the air flowing past a flying object is smooth because less energy is imparted to the airflow when it is smooth than when it is turbulent.

Air that flows smoothly over a surface is said to be laminar. In laminar flow, the air acts as if it were in layers above the surface of the vehicle. These layers of air slide over each other smoothly, and the velocity of each layer increases in a smooth and regular distribution moving further away from the surface. In a turbulent flow, however, the layers of air mix together creating an irregular and uneven pattern.

A simple analogy is to compare the layers of air to lanes of traffic on a highway. Each molecule of air can be thought of as an individual car. In a laminar flow, the "slow lane" is closest to the surface, and lanes further away become increasingly faster. There is no interaction between the different layers, so a molecule from a slower layer cannot "switch lanes" and move to a faster layer. The same cannot be said of a turbulent flow. Here, molecules are free to move from layer to layer, causing the air flow to randomly speed up in some places and slow down in others. The end result is a chaotic and unpredictable pattern of air that creates greater drag than a smooth, laminar airflow.

Many factors of rocket design can increase the drag it experiences in flight. One of the most important of these factors is the shape of the nose. The ideal aerodynamic nose shape is primarily related to the speed at which the rocket flies. Moreover, the same principles hold true for aircraft, missiles, bombs, and other flying vehicles as well. In fact, it is often possible to tell what speed regime an aerial vehicle was designed to fly in simply by observing the shape of its nose.

For example, the ideal nose shape for vehicles that fly at subsonic speeds, defined as less than the speed of sound, is more rounded. That is why commercial aircraft like the Boeing 777 usually have rounded noses called parabolic nose shapes.

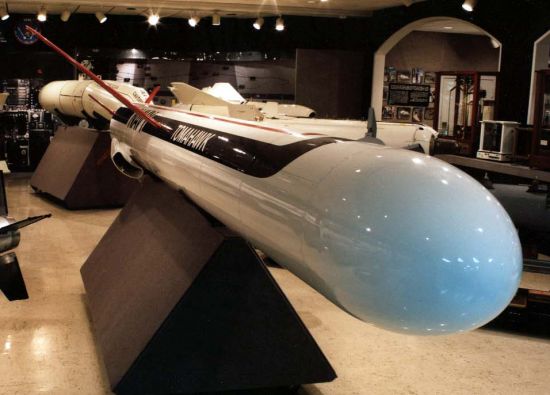

Similar nose shapes can be seen on other subsonic vehicles, such as the Tomahawk cruise missile pictured below.

The ideal nose of a high speed, supersonic fighter like the F-15 Eagle, on the other hand, is a more pointed shape like a cone. Most supersonic aircraft, rockets, and missiles use a nose shape very similar to a cone but a little more rounded to provide more internal volume. This shape is called an ogive (pronounced "oh-zheeve" or "oh-zhive").

The faster the vehicle is designed to go, the more pointed the ideal aerodynamic nose shape becomes. Compare the nose of the Mach 2 F-15 with that of the Mach 5 Phoenix air-to-air missile shown below. The limitation on nose shape is temperature. At very high Mach numbers, the nose must become more rounded than the ideal low-drag shape in order to spread the high temperatures over a larger area and prevent the nose from melting.

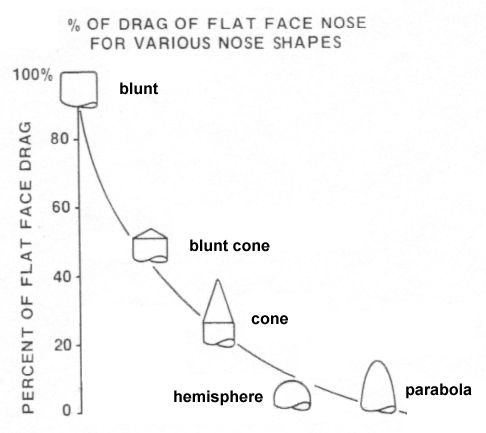

The ideal nose shape for a rocket that minimizes its drag and maximizes its altitude depends on how fast the rocket is designed to travel. Most model rockets that you can buy in a store fly well below the speed of sound. As a result, the ideal nose for a model rocket is not the pointed cone or ogive shape you might expect, but the more rounded parabola. The shape that produces the highest drag is the blunt, or flat-face shape. Several common nose shapes and the drag they generate as a relative percentage of the blunt nose are compared in the following figure.

Proof of these trends can be seen in the results of experimentation conducted by yours truly. The purpose of the project was to determine the effect of different nose shapes on the altitude of a model rocket. Four nose shapes were tested, a parabola, ogive, cone, and a blunt shape, similar to those shown below.

All tests were conducted using the same rocket body and using solid propellant motors of equal thrust. In addition, each nose was adjusted to the same length and weight to ensure that only the nose shape would vary from flight to flight. A ground-based altitude tracker based on simple trigonometry was used to measure the maximum altitude achieved on each flight. The results of the study are illustrated in the following figure.

The only variable that could not be controlled was the weather, particularly the strength and direction of the local winds. Though the wind did vary over the course of the experiments which could affect the accuracy of the results, the trends do clearly confirm the characteristics discussed earlier. The parabolic nose produced the best performance by far, with an average maximum altitude of 308 ft (94 m). At the other extreme, a blunted nose was the worst performer at an average altitude of 237 ft (74 m), a decrease of nearly 25%. The conical and ogival noses were pretty comparable, achieving average altitudes 15% and 12% lower than the parabola, respectively.

In conclusion, the shape of the nose does indeed have a significant impact on the height it can reach. For most

model rockets that fly at speeds far less than the speed of sound, a rounded, parabolic shape is ideal to minimize

drag and reach the highest altitude. If you are designing a high-performance rocket that can reach supersonic

speeds, however, a more pointed nose like the ogive is the ideal shape.

- answer by Jeff Scott, 23 November 2003

Read More Articles:

|

Aircraft | Design | Ask Us | Shop | Search |

|

|

| About Us | Contact Us | Copyright © 1997- | |||

|

|

|||